The basic premise of garden room construction is the same throughout the industry – insulated panels built in factory conditions, delivered to site and quickly assembled creating a room suitable for year round occupation.

Terms like traditional timber frame system or structural insulated panels (SIP’s) are widely used on sales particulars, and they are indeed the two leading garden room construction systems, but the terms don’t relate to a benchmark system that is used by all suppliers – one suppliers SIP’s or timber frame build up, can be a very different beast to another suppliers!

We thought it would be interesting to look at the different types of build up – its important that you compare like with like when searching for a garden room, this ensures you make an informed buying decision.

As you will see there are some garden room build-ups that are the same as those used in house construction and others that are pared down versions, still containing all the essential elements.

House quality constructions typically have the best thermal performance as they meet or exceed current Building Regulations, but the structure is often thicker, and some buyers prefer a thinner wall which creates more space in the room.

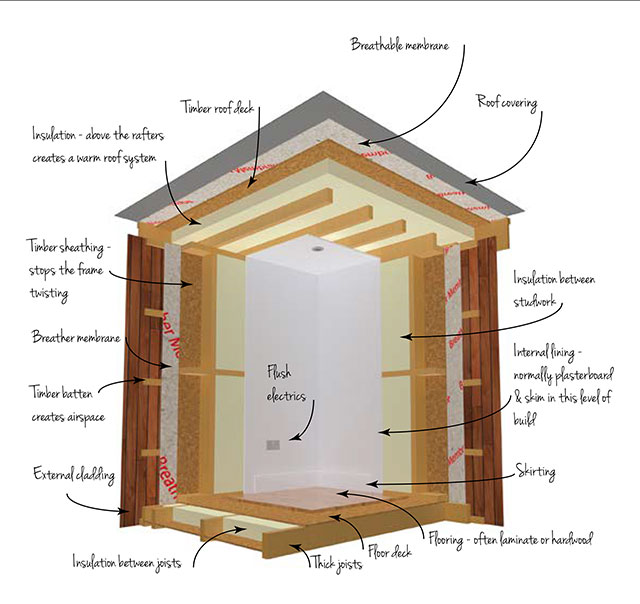

FULL TIMBER FRAME CONSTRUCTION

This timber frame build up is like that used in timber frame housing. The walls are around 150mm thick, made up of several levels of material, layers of membrane and air spaces.

The insulation is fitted between the timber frame and will differ between suppliers, some use fibreglass batts, whilst others used foil backed rigid sheets.

Modern timber frame systems like this normally have warm roof systems, whereby the insulation is placed above the rafters, this overcomes problems with ventilation in the roof build up.

This is the Rolls Royce of timber frame garden rooms, and will create a very sturdy building which will be comfortable to use all year round.

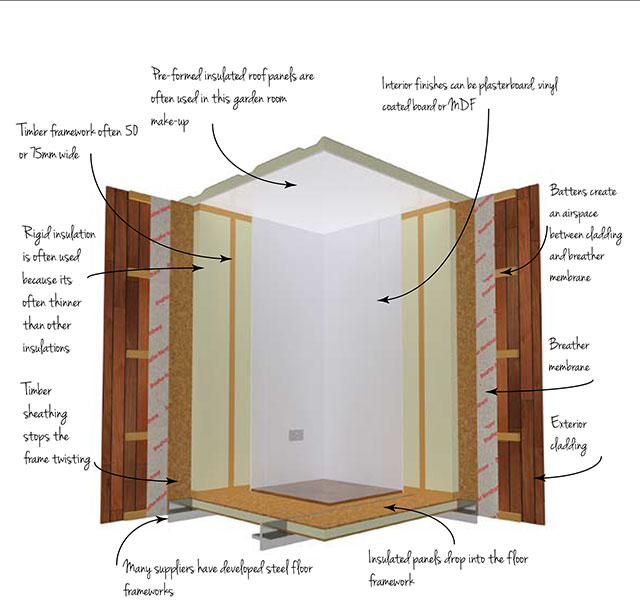

TIMBER FRAME CONSTRUCTION

This page shows another form of timber frame construction typically used in garden room construction.

Like the previous example the basic framework is made up of a skeleton of uprights and horizontals. In some ways this build up is a pared down version of the full timber frame construction mentioned, the overall wall thickness is narrower at about 75 -100mm, this is partly the result of higher performance insulations being used.

Suppliers of this type of build-up have also honed the design of the floor, many using metal frameworks into which insulation and flooring ‘sandwiches’ are dropped.

The roof on this style of garden room is often a preformed insulated panel which locks together, one side creates the ceiling of the room, the other side is the external roof covering.

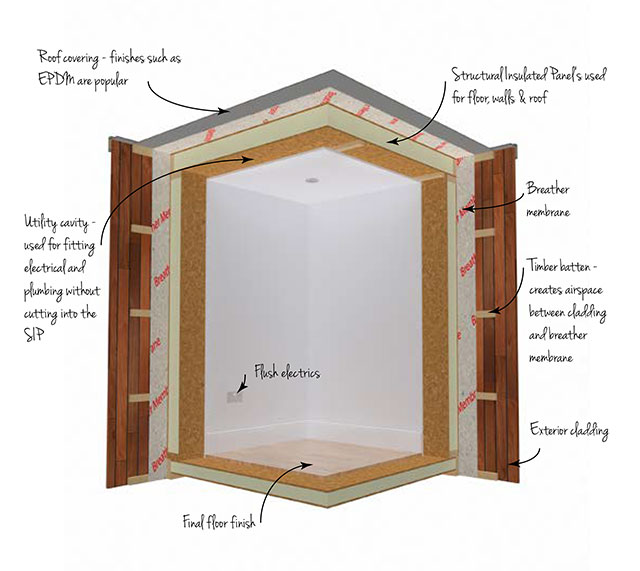

HOUSE QUALITY SIP’s

Structural Insulated Panel’s (SIP’s) are fast replacing traditional timber frames in garden room construction, but like timber frames come in different forms.

This build up is like you’d find used on the houses you see on shows like Grand Designs. Garden room suppliers who used this system buy their SIP’s from the same manufacturers as house builders.

Like the full timber frame shown, this system is built up of layers of material, breathable membranes and air spaces, the overall thickness of this build up is around 150mm.

The beauty of the SIP’s building system is that the insulation is wrapped around the building, not broken up by the timbers of the framework.

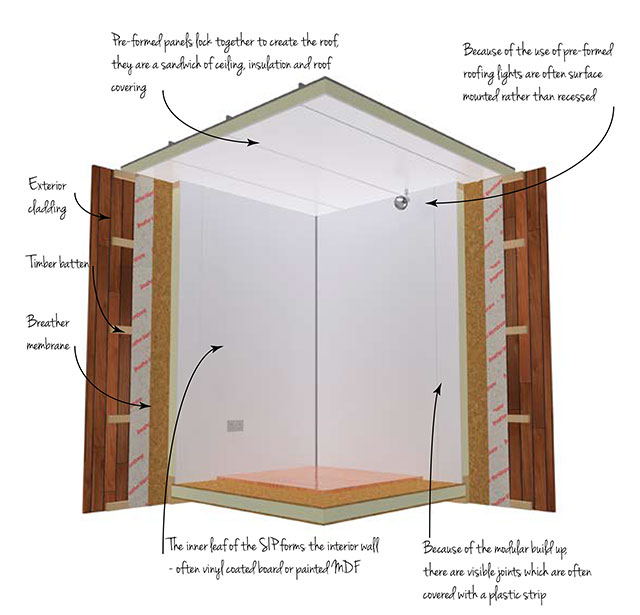

CUSTOM BUILT SIP’s

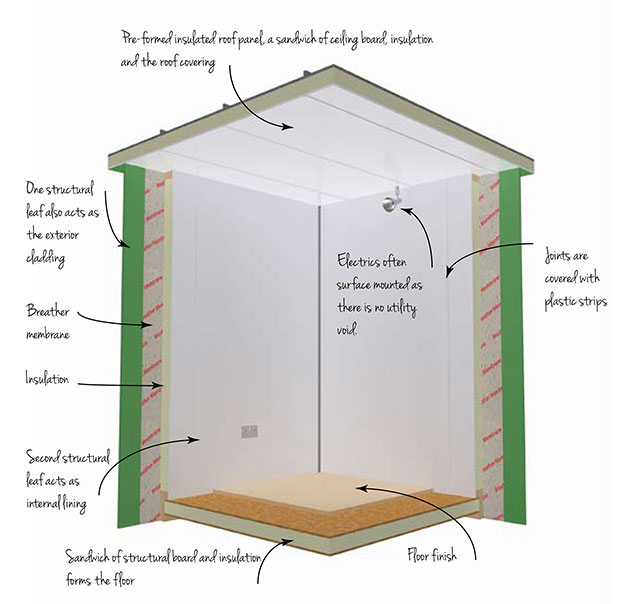

The inner leaf of the SIP forms the interior wall – often vinyl coated board or painted MDF.Because of the modular build up, there are visible joints which are often covered with a plastic strip.

Many garden room suppliers make their own version of the Structural Insulated Panel, taking their chosen components and bonding them together, the key elements will be a structural board such as OSB or plywood, rigid insulation and an inner leaf which also forms the interior wall finish – often a vinyl coated board or a painted MDF.

It’s interesting to note that some suppliers include timber studs in their panel makeup, so these custom built SIP’s are actually a hybrid of both the modern structural insulated panel and the traditional timber frame build up.

THE ALL IN ONE SIP

Electrics often surface mounted as there is no utility void. Joints are covered with plastic strips.

This is another garden room build up that is manufactured in house by some suppliers, often found on more budget models. It is actually just four layers – the external structural board, often plywood or a eco board, made-up of resin and wood dust which forms the exterior cladding, a breather membrane, rigid insulation and then the internal leaf which forms the final wall covering too.

Garden rooms built with this type of SIP have narrow walls often only 50 – 75mm thick.

The roof of these buildings makes use of the pre-formed insulated panels we have described elsewhere, making this style of construction very quick to build.